Hanna Machining

Engineering Insight Leads to Product Design Assistance You Can Trust.

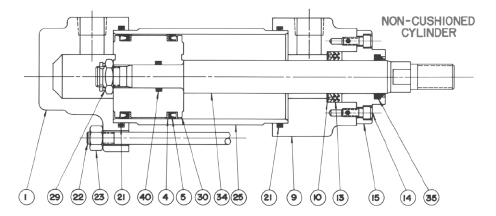

In addition

to our traditional offerings of high quality hydraulic

and pneumatic cylinders, Hanna now delivers state

of the art contract machining and fabrication services

for one-off to high volume industrial parts.

We can design, fabricate and assemble, weld, and paint your products — all under one roof. This allows us to keep our costs down while passing the saving onto you.

Our team of engineers, cross-trained machinists, and welders are at the ready to take on any project — large or small, simple or complex.

Our machinery is capable of machining any material from simple plastics to exotic steels up to 64.96” in diameter, 456.00” in length, and up to 11,000 pounds.

Our QA/QC team will ensure your products meet your drawings and specifications, and industry standards like 10 CFR 50 Appendix B

Drill Spool Machining Process- 4140 Heat Treated Material

BEFORE

DURING

AFTER

Certifications and Qualifications

- US NRC 10 CFR 50 Appendix B

- ASME Section 9

- ASME N Stamp

- ASNE U Stamp

- AWS D1.1

- CAGE Code 7D4J9

- IEEE Qualification

- MIL-I-45208

- MIL-Q-9858